Electronics & PCB Development

OEM Electronics development and manufacturing

Our Electronics Production Package is tailored for startups, newcomers, and established companies looking for cost-effective custom electronics manufacturing. Whether you're bringing a brand-new product idea to life or refining an existing design, we provide the expertise and resources to make it happen. From defining functionality and planning PCBs to assembling components into cases or products, we handle every step with precision.

The electronics manufacturing process involves careful attention to multiple elements: internal chip design, external case design, assembly, packaging, and production line setup. As your trusted electronics manufacturer, we offer flexibility to either adapt existing designs or create entirely new products. By leveraging standard components, bundling small orders, and partnering with reliable electronics suppliers, we help you achieve high-quality results at lower costs.

Our solutions are designed to save you time, energy, and money, making the process as smooth and efficient as possible. Whether you're a startup launching your first product or a business scaling production, we’re here to minimize your investment and maximize your success. Partner with us—an experienced electronics contract manufacturing company—and bring your product vision to life!

Electronics Development Lifecycle

Develop a Concept

Every great product starts with a concept. We work closely with you to refine your idea, consulting on functionality, design layout, and technical requirements. Once the concept is clear, we provide detailed technical drawings to outline dimensions, components, and necessary certifications to bring your product to life.

CAD File Creation

Our engineers create 3D CAD files and renderings of your electronics design, giving you a complete 360° view of the product. This step allows you to visualize every detail, troubleshoot potential mechanical challenges, and prepare for enclosure design, whether it’s a case or a custom housing.

PCB Design and Optimization

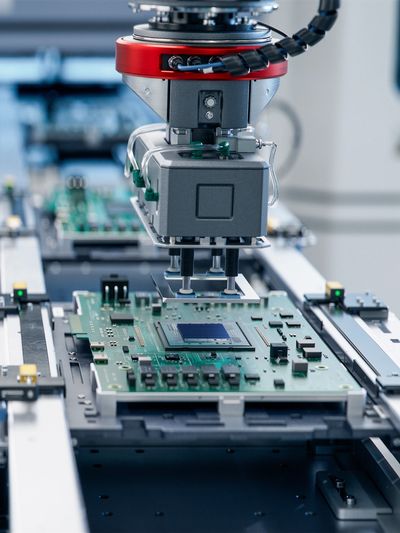

In parallel, our team designs the printed circuit board (PCB) that powers your product. We focus on creating a cost-effective PCB layout by collaborating with reliable electronic parts suppliers and considering mass production factors. After assembly, we debug the PCB to ensure flawless operation.

Prototyping Your Product

Prototyping is essential to identify potential issues that might only surface when the product is physically handled. We deliver prototypes faster than standard PCB manufacturers, including 3D-printed enclosures and electronics assembly options, to ensure you can evaluate and refine your product early on.

Finalize the Bill of Materials (BOM)

Once the design and prototype are approved, we generate a comprehensive Bill of Materials (BOM). This document lists all components, streamlines production costs, and identifies potential bottlenecks. With the BOM finalized, we plan mass production and coordinate assembly, certification, and packaging needs.

Mass Production and Quality Control

The final step is setting up the production line in our assembly facility. We coordinate with trusted suppliers and inspect every production batch at multiple stages to identify and resolve any issues. Alternatively, we can deliver sub-assemblies for further processing at your end. Our goal is to ensure your product is delivered on time, with the highest quality standards.

Electronics

Prototype Phase - $697

Includes circuit diagram, PCB schematic and 3D design, and other technical design files.

Manufacturing Phase - $297

Includes first article inspection (FAI), production plan, first production run, assistance with required certifications, and quality control plan.

*For simple custom or standard designs, the development and sample cost have to be checked individually depending on the product.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.